- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Calibrating a HART Smart Pressure Transmitter

Pressure transmitter manufacturers have improved the accuracy and technology designed into these smart pressure measurement devices. Many conventional calibration tools have become inadequate or simply unable to test and calibrate these high accuracy pressure transmitters. Better test solutions are required.

Verifying and documenting the performance and adjusting a HART smart pressure transmitter can require a bucket full of tools. In the past, it was common to use a HART communicator but now performing this task with a HART-enabled calibrator like the Fluke 754 Documenting Process Calibrator or Fluke 2271A Industrial Pressure Calibrator simplifies the task and reduces what you need to carry.

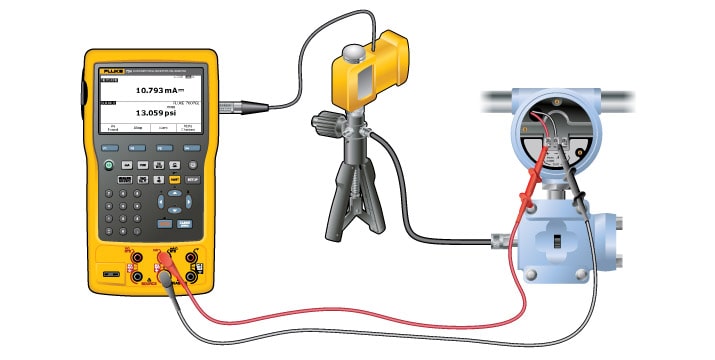

In the example of using the Fluke 754 as illustrated above, before going to the field, install the pressure module adapter to the hand pump with thread seal. Once the adapter is properly installed on the pump, changing modules to different pressure ranges is a snap, no tools required.

To get the accuracy needed to test these new high accuracy transmitters, match the pressure measurement standard range closely to the device tested. For example, use a 100 psi pressure module to calibrate and test a transmitter ranged at 100 psi. Industry standards suggest the measurement standard should be 4-10 times more accurate than the device being tested, so best-in-class accuracy is required.

The Fluke 754 Documenting Process Calibrator-HART utilizes the 750P series pressure module and has the HART functionality built in to enable smart trims on transmitters. It can also document transmitter performance before and after adjustment and calculate pass/fail errors.

To perform the test:

- Isolate the transmitter from the process being measured and its loop wiring. If measuring the mA signal across the transmitter test diode leave the wires intact, but note this method does not give the best mA measurement accuracy.

- Connect the mA measurement jacks of the 754 to the transmitter.

- Connect the pressure module cable to the 754 and connect the transmitter test hose from the hand pump to the transmitter.

- Press the HART button on the calibrator to see the configuration of the transmitter.

- Press HART again and the calibrator will offer the correct measure/source combination for the test. If documenting the calibration press As-Found, input the test tolerance and follow the prompts. If the measured mA signal at the test points is found within tolerance the test is complete. If not, adjustment is required.

- Select, adjust, and trim the pressure zero, mA output signal and input sensor.

- After adjustment select As-Left, document the condition of the transmitter and after adjustment and if the test passes, it is complete.

Recommended Products

700G Precision Pressure Gauge Calibrator

2700G Series Reference Pressure Gauges

754 Documenting Process Calibrator - Hart

2271A Industrial Pressure Calibrator

Recommended Resources

Pressure calibration applications and solutions - application note

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- Service Request (RMA)

- Service Plans

- Technical Support

- Knowledge Base

- Accreditations

- Authorized Service Centers

- Calibration Certificates

- Community Forum

- My MET/SUPPORT

- Product Manuals (User Guides)

- Safety Data Sheets (SDS)

- Recycle Program

- Safety, Service, and Product Notices

- Software Downloads

- Warranties

- Tools

- About Us