- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

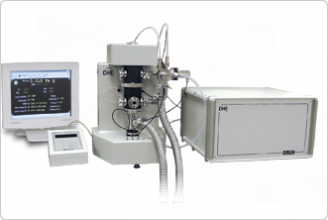

Reference level calibration system for very low pressure

- Covers the range of 0 to 15 kPa (113 Torr) in gauge, absolute differential and absolute modes.

- Resolution to 1 mPa (0.0075 mTorr, 0.000004 in. H2O).

- Measurement uncertainty to:± (5 mPa + 30 ppm of reading) in gauge and absolute differential mode, ± (8 mPa + 30 ppm of reading) in absolute mode.

- Fully automated operation including pressure control and DUT data acquisition allows multi-increment tests to be run unattended. Integrated thermal transpiration correction available when needed.

FPG8601 addresses the need for a means of maintaining long term traceability with very low uncertainty in the pressure range under that covered by conventional piston gauges.

The measurement range covered is from zero (0.5 Pa in absolute) to 15 kPa (112 Torr, 2.2 psi) in both gauge and absolute modes. Measurement uncertainty is the combination of ± 30 ppm of reading and a low end threshold component low enough to support the calibration of typical transfer standards with ranges as low as 130 Pa (1 Torr, 0.5 in. H2O), and even 13 Pa (100 mTorr, 0.05 in. H2O).

FPG8601's measurement uncertainty is documented in a complete uncertainty analysis. The instrument's stability over time is dependent on the stability of a tungsten carbide piston-cylinder and stainless steel mass, allowing FPG8601's calibration interval to be the same as that of conventional piston gauges with no other special maintenance requirements.

In addition to its excellent metrological performance, FPG8601 offers fully automated operation; reasonable size and weight and has no environmental requirements beyond those typically found in a high end metrology laboratory.

Operating Principles

Measurement

FPG8601 operates on the well known piston gauge principle in which pressure applied to the effective area of a piston-cylinder is transformed into a proportional force. However, rather than being balanced against masses accelerated by gravity, the force resulting from pressure is measured by a force balanced load cell to which the piston is attached. As the pistoncylinder is fitted with pressure chambers at both its top and bottom, the reference pressure against which pressure is defined can be changed (atmosphere for gauge, vacuum for absolute). Zeroing the load cell with the high and low chambers at a common pressure, tares out the mass of the piston and any other forces not due to measured pressure, allowing pressure measurement to start from zero. The value of the differential pressure applied is calculated from the effective area of the piston-cylinder and the net force value measured by the load cell.

To avoid the instability and mechanical complexity of centering the piston by rotating it in the cylinder, the FPG piston is centered by the flow of an independent lubricating gas pressure in the piston-cylinder gap. The gap is conical, narrowing symmetrically toward the piston's extremities. The piston-cylinder gap is 1 to 6 μm and the lubricating pressure is 40 kPa greater than the reference pressure, keeping flow into the measurement chambers very low (less than 1 sccm total). The force across the piston is transmitted to the load cell through a gimbal coupling system that holds the piston at its center of gravity. The connecting system passage is also used to supply the piston-cylinder lubricating gas. The load cell is enclosed in a hermetic chamber through which the lubricating gas flows. The design of the load cell chamber contributes to maintaining its temperature constant and the lubricating gas is conditioned to assure relative humidity.

Control

The FPG8601 pressure controller operates by the adjustment of flow across a flow restriction. The upstream side of the restriction is connected to the upper FPG pressure chamber and the downstream side is connected to the lower FPG pressure chamber and to atmosphere or to an independent vacuum source for absolute mode operation. Several flow restrictions of different conductance are included in the controller and the one appropriate for the pressure range is selected automatically. Two mass flow controllers (MFC), one for coarse pressure control and the other, lower range, for fine pressure control, are used in parallel to adjust the flow in a feedback loop. Control is based on the difference between the pressure set point and the FPG pressure measurement. A two stage pressure regulator whose second stage is referenced to the downstream side of the flow restrictions supplies a stable input pressure to the mass flow controllers.

Automated Operation

The FPG8601 includes a Windows® based system controller. The system controller communicates with the FPG8601 hardware and devices under test. FPG Tools™ software monitors and controls FPG operation and supports a wide variety of high level functions, including running fully automated, unattended test sequences with device under test data acquistion. All FPG and device under test data are recorded in delimited data files that are easily downloaded to other applications for analysis. Some of the functions of FPG Tools software include:

- Measurement mode (gauge/absolute) changes

- Auto zero and auto span the load cell

- Data point averaging time adjust

- Excessive change in operating conditions alarms

- Thermal transpiration corrections in low absolute

- Device under test setup

- Test procedure definition and storage

- Fully automated test execution

- Real time test result plotting

Gauge, Absolute and Absolute Differential Measurement Modes

FPG8601 supports three different measurement modes:

- Gauge mode: The lower chamber of the FPG and the "low" side of the test are connected together and left open to atmosphere.

- Absolute mode: The lower chamber of the FPG is evacuated and the residual vacuum is measured by a vacuum gauge. This mode is used to calibrate sealed absolute DUTs.

- Absolute differential mode: The lower chamber of the FPG and the "low" side of the test are connected together and evacuated. This mode is used to calibrate differential DUTs relative to vacuum.

Bench Top System without Special Environmental Requirements

FPG8601 can be installed on a high quality, 2 m (6 ft.) laboratory bench. The pressure controller is often mounted under the bench. Location of the vacuum pumps needs to be considered when absolute pressure capability is included. A custom mounting bench can be supplied with the system if desired.

The environmental requirements for FPG8601 operation are those typically found in a high end metrology laboratory.

Installation and Training Service

Three to five days of installation and training service is recommended with a new FPG8601 installation. This service includes setup and testing of the FPG8601 system as well as training of users on operation and maintenance, including running typical tests. Training can be supplied at Fluke Calibration's Phoenix, Arizona facility prior to delivery and/or at the installation location following delivery.

General |

|

| Power Requirements | FPG8601 85 to 264 VAC, 50/60 Hz, 60 VA max VLPC 85 to 264 VAC, 50/60 Hz, 70 VA max |

| Normal Operating Temperature Range | 20 to 26 °C |

| Ambient Temperature Stability | 0.1 °C/minute max rate |

| Weight | FPG8601 Platform 30 kg (66 lb) FPG8601 Terminal 2 kg (4.4 lb) VLPC Pressure Controller 41 kg (90.4 lb) |

| Dimensions | FPG8601 Platform 53 cm H x 36 cm W x 35 cm D (21 in. x 14 in. x 14 in.) FPG8601 Terminal 12 cm H x 15 cm W x 20 cm D (4.7 in. x 6 in. x 8 in.) VLPC Pressure Controller 31 cm H x 51 cm W x 53 cm D (12.2 in. x 20 in. x 21 in.) |

| System Controller | Runs FPG Tools™, Windows® operating system, RS232 and IEEE-488 interfaces to FPG and DUT data acquisition |

| Overall Pressure Range | 0 to 15 kPa gauge, absolute, absolute differential |

| Test Medium | N2 or Air |

| Mode Change Time | Absolute to Gauge 30 minutes Gauge to Absolute 1 hour |

| Vibration | Same as conventional piston gauge, vacuum pumps must be connected by flexible tubing |

| Pressure Supplies | Piston-Cylinder Lubrication Gas(FPG8601): 700 to 800 kPa, clean, dry N2 or Air FPG Reference Vacuum (for absolute modes): Turbo pump: 378 m3/hr typical, 8.10-6 Pa ultimate pressure Rotary vane pump: 16.5 m3/hr, 0.2 Pa ultimate pressure VLPC Supply : 700 to 800 kPa, clean, dry N2 VLPC Vacuum: 10 m3/hr @ 0.5 Pa Drive Air (FPG8601 and VLPC): 400 to 700 kPa shop air |

| Pressure Connections | Test high (FPG8601): KF16 Test low (FPG8601): KF16 Vacuum Ref (FPG8601): KF25 Vacuum (FPG8601): 1/8 in. NPT F Drive/lubrication (FPG8601): 1/8 in. NPT F Supply (VLPC): 1/8 in. NPT F Drive (VLPC): 1/8 in. NPT F Vacuum (VLPC): KF25 |

Pressure Measurement |

|

| Overall Range | 0 to 15 kPa gauge, absolute, absolute differential |

| Temperature Effect | Instrument temperature monitored and alert provided when rate and/or magnitude of temperature change is significant to performance |

| Resolution | Standard: 0.010 Pa High Resolution Option: 0.001 Pa |

| Typical Pressure Measurement Uncertainty | Standard: Gauge, absolute differential modes: ± (0.020 Pa + 30 ppm rdg) Absolute mode: ± (0.025 Pa + 30 ppm rdg) High Resolution Option: Gauge, absolute differential modes: ± (0.005 Pa + 30 ppm rdg) Absolute mode: ± (0.008 Pa + 30 ppm rdg) |

| Typical Residual Vacuum in Absolute Mode | With Turbo Molecular Pump: 0.04 to 0.1 Pa With Rotary Vane Pump: 0.3 Pa to 0.4 Pa |

Pressure Control |

|

| Control Ranges (Pa) | Gauge mode: 5 overlapping control ranges Minimum pressure: 0 Minimum controlled pressure: 0.1 Pa Absolute mode: |

| Control Precision | Standard: Gauge mode: ± (0.020 Pa + 100 ppm of range) Absolute modes: ± (0.020 Pa + 30 ppm of range) High Resolution Option: |

| Nominal Test Volume | Gauge Mode: Up to 20 cc/side (high and low) Absolute Mode: Up to 500 cc/side (high and low) |

| Typical Pressure Setting Time | 1 to 2 minutes, dependent on test volume |

Piston-Cylinder |

|

| Nominal Size | Diameter: 35 mm Area: 10 cm2 |

| Piston Material | Tungsten carbide |

| Cylinder Material | Tungsten carbide |

| Mounting System | Non-rotating, self-centering by independently, centrally supplied, lubricating pressure |

| Piston-Cylinder Gap | Symetrical conical gap with dual taper from 6 microns at central lubrication point to 1 micron at cylinder ends |

| Lubricating Gas Quality | Clean, dry N2 or Air, on-board conditioning to 40 to 70 % R.H. |

| Lubricating Gas Pressure | Gauge Mode: 40 kPa gauge Absolute Modes: 40 kPa absolute Lubricating Gas Flow: < 1 sccm total to the high and low chambers |

Secondary Measurement |

|

| Piston-Cylinder Temperature (°C) | Range: 0 to 40 Resolution: 0.01 Uncertainty: ± 0.1 |

| Residual Vacuum (Pa) | Range: 0 to 13 Resolution: 0.001 Uncertainty: ± (0.5 % rdg + 5 mPa) |

Monitoring Measurement |

|

| Lubrication Gas Temperature (°C) | Range: 0 to 40 Resolution: 0.1 Uncertainty: ± 0.2 |

| Lubrication Gas Pressure (kPa) | Range: 0 to 200 absolute Resolution: 0.001 Uncertainty: ± 0.1 |

| Lubrication Gas Humidity (%RH) | Range: 5 to 95 Resolution: 1 Uncertainty: ± 10 |

| Model Name | Description |

|---|---|

| FPG8601-SYS |

Force Balanced Piston Gauge System with standard resolution Includes:

|

Accessories common to all models:

| Accessory | Description |

|---|---|

| FPG8601-MODE-V-REF |

Vacuum reference mode |

| MS-8601-2 |

2.0 kg mass set w/hanger |

| BENCH-8601-ABS |

Various vacuum pump choices for the FPG reference and the VLPC controller in absolute modes (consult your Fluke pressure calibration sales representative) |

| FPG8601-RES-HIGH |

High resolution (1 mPa) |

| Product Manuals |

|---|

| Application Notes |

|---|

| Data Sheets |

|---|

| Software |

|---|

| COMPASS for Pressure Calibration Software Download/Upgrade |

| FPGTools PC Based Software |

| Instruction Sheets |

|---|

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- Service Request (RMA)

- Service Plans

- Technical Support

- Knowledge Base

- Accreditations

- Authorized Service Centers

- Calibration Certificates

- Community Forum

- My MET/SUPPORT

- Product Manuals (User Guides)

- Safety Data Sheets (SDS)

- Recycle Program

- Safety, Service, and Product Notices

- Software Downloads

- Warranties

- Tools

- About Us

Sidebar Request a Quote

Request a quote