- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Replacing a DPI 515 with the 6270A Modular Pressure Controller/Calibrator

The 6270A Modular Pressure Controller/Calibrator is an effective drop-in replacement for the Druck DPI 515 in most applications. In addition to the basic functions required to replace the DPI 515, the 6270A also offers advanced design, performance, and features to improve pressure calibration capabilities. This application note summarizes some of the benefits of upgrading to the 6270A and provides step-by-step instructions for configuring and installing the 6270A as a replacement to the DPI 515.

Benefits of upgrading

There are many benefits to upgrading from the legacy DPI 515 to the 6270A Modular Pressure Controller/Calibrator, including:

- Workload coverage

- Measurement performance

- Control performance

- Maintainability/serviceability

- Expandability

Let’s explore these benefits in more detail.

Workload coverage

The DPI 515 could be configured with up to two measurement ranges. These ranges were completely independent, which allowed flexibility in coverage since one range could be a high pressure and the second range could be a very low pressure. The drawback is its ability to cover the middle ranges. Each range has a percent full-scale specification and is fixed. It cannot be re-ranged to cover lower pressures. The 6270A resolves this issue by allowing for more ranges (up to five) to be installed at one time and allowing for easy re-ranging of the unit by replacing modules. You still have the very wide coverage of vacuum to 3000 psi, but now you have coverage at all of the pressures in between.

Measurement performance

The Druck DPI 515 utilizes silicon-based pressure sensors for its onboard calibration reference standards. While its headline measurement specification is 0.01% of full scale of each sensor, it is important to remember that there is also an additional specification of 0.01% reading for long-term measurement stability, resulting in a one-year measurement uncertainty specification of potentially as great as 0.02% at full scale.

Fluke Calibration 6270A offers two pressure measurement modules class options to replace and improve upon the function of the DPI 515 while balancing cost and performance:

- The silicon-based cost-effective PM200 module offers 0.02% full scale total one-year measurement uncertainty specification. This provides an equal measurement specification to the DPI 515 at the full scale for an equivalent range. In many cases, one or two PM200 modules can be used to replace the equivalent option of each DPI 515 range.

- The resonating quartz-based high-performance PM600 module offers 0.01% reading total one-year measurement uncertainty specification from 30% to 100% of the module full scale. Most of the PM600 modules offer gauge, absolute and vacuum measurement standard. In many cases, one PM600 module can effectively replace the function of both ranges and the barometric reference option of the DPI515.

Control performance

The 6270A provides control precision of 0.001% of the active range. The DPI 515 had a specification of 0.001% for ranges of 1000 psi and below and 0.0015% for higher ranges. While these specifications look very similar, the 6270A can be significantly better depending upon how it is configured. Since the 6270A is not limited to two ranges like the DPI 515, but can instead have as many as five ranges, lower pressure ranges can be included. This results in better control performance at lower pressures than the DPI 515.

Maintainability/serviceability

The 6270A is designed with a focus on maintenance and service. The modular design allows for reduced downtime during recalibration. Control functionality is also encapsulated in a module, making troubleshooting and repair of any control performance issues. The focus on serviceability is seen throughout the design. For example, the removable connection manifold allows for easy repair if the port connection threads are damaged due to misuse.

Expandability

Your calibration needs change with time. The 6270A can change with your needs. You can change the pressure range or measurement performance of the instrument by adding pressure measurement modules. This can be done without sending any part of the instrument back to the factory for reconfiguration. Simply install the new pressure measurement modules and start controlling pressure.

The DPI 515 is static in its configuration. Whatever ranges it was configured for originally are what they will be for the rest of its life. Your needs have potentially changed since the DPI 515 was acquired, but the DPI 515 can’t be altered to meet them.

Configuring a 6270A

Selecting a pressure module

DPI 515 controllers were configured with one or two ranges and an optional barometric reference sensor to allow operation in absolute pressure mode. The 6270A can accommodate up to five installed pressure modules with 35 module options to choose from, so there are numerous ways to configure a 6270A to replace any configuration of DPI 515.

To select the right pressure modules for the 6270A, first consider the required pressures and accuracies for your application. There are two classes of pressure measurement modules for the 6270A. The PM200 modules have a one-year specification of 0.02% full scale. For most applications where the performance of the DPI 515 was sufficient, the PM200 modules are a good choice.

The PM600 modules have a one-year specification of 0.01% reading from 30% to 100% span. If the DPI 515 had multiple ranges where the lower range was greater than approximately 30% of the higher range, then both channels can be replaced with a single PM600 module.

The table below shows the PM200 and PM600 modules recommended to replace each published DPI 515 range.

| DPI 515 Ranges | Avaliable as PM200 | Available as PM600 | |||

|---|---|---|---|---|---|

| 10 | inH2O | gauge | 2.5 kPa | PM200-BG15K | PM600-BG15K* |

| 1 | psi | gauge | 7 kPa | PM200-BG15K | PM600-BG15K |

| 3 | psi | gauge | 20 kPa | ||

| 5 | psi | gauge | 35 kPa | PM200-BG35K | PM600-G100K* |

| 10 | psi | gauge | 70 kPa | PM600-G100K* | |

| 15 | psi | gauge | 100 kPa | PM200-BG100K | PM600-G100K |

| 30 | psi | gauge | 200 kPa | PM200-BG200K | PM600-G200K |

| 50 | psi | gauge | 350 kPa | PM600-A1.4M* | |

| 100 | psi | gauge | 700 kPa | PM200-G700K | PM600-A700K |

| 150 | psi | gauge | 1 MPa | PM200-G1M | PM600-A1.4M* |

| 300 | psi | gauge | 2 MPa | PM200-G2M | PM600-A2M |

| 500 | psi | gauge | 3.5 MPa | PM200-G3.5M | PM600-A3.5M |

| 1000 | psi | gauge | 7 MPa | PM200-G7M | PM600-A7M |

| 1500 | psi | gauge | 10 MPa | PM200-G10M | PM600-A10M |

| 2000 | psi | gauge | 14 MPa | PM200-G14M | PM600-A14M |

| 3000 | psi | gauge | 20 MPa | PM200-G20M | PM600-A20M |

* The exact range is not available but it is within the percent reading region of the next highest pressure range available.

Measuring barometric reference pressure

A barometric reference sensor was an available option on the DPI 515. Choosing this option allowed the instrument to be used in absolute mode. If gauge mode PM200 modules are used with the 6270A, then a barometric reference option is recommended for operation in absolute mode. There are two modules available that can be used for measuring the barometric reference pressure.

| Model | 1 Year Specification |

|---|---|

| PM200-A100K | 0.1 % FS |

| BRM600-BA100K | 0.01 % reading |

When a barometric reference sensor is used to allow for absolute mode pressure measurements, the performance of the barometer has a greater impact on the overall measurement at lower pressures compared to higher pressures. For many applications, the PM200-A100K is acceptable for pressure ranges of 500 psi or greater. The BRM600-BA100K is preferred for lower pressure ranges.

The majority of PM600 modules are inherently absolute mode. They are capable of measuring in both gauge and absolute mode without the use of an additional barometer. Adding the barometer can improve the measurement performance in absolute mode. In most situations where the DPI 515 measurement performance was acceptable, the additional improvements provided by the barometer are not necessary.

Selecting connection types

There are three versions of the 6270A main chassis. The difference between the versions is the connection types on the back of the instrument. The connection types can be changed by removing and replacing the rear connection manifold. Removal of the manifold is done by removing the four screws and sliding the manifold out the back of the instrument.

| Model | Supply, Exhaust, Test, and Reference Connections | Vent Connection |

|---|---|---|

| 6270A-NPT | ¼ NPT | 1/8 NPT |

| 6270A-BSP | ¼ BSP (parallel) | 1/8 BSP (parallel) |

| 6270A-7/16 | 7/16-20 SAE | 5/16-24 SAE |

Installation and setup

Rackmount installation

An optional rackmount kit is available for the 6270A. This kit allows for installing the 6270A in a standard 19-inch rack, just like the optional rackmount kit that was available for the DPI 515. Both the 6270A and the DPI 515 are the same height (3U), so they can occupy the same vertical space in the cabinet.

Single range physical connections

Replacing a Single Range DPI 515 is straightforward. Simply connect the device under test to the 6270A test port instead of the DPI 515 outlet. Connect the supply pressure (previously connected to the DPI 515 supply+ port) to the supply port on the 6270A. If there was a vacuum pump connected to the DPI 515 supply port, connect it to the 6270A exhaust port. For ranges above 100 psi, the supply pressure requirements for the DPI 515 and the 6270A are the same (10% above the full-scale range). For ranges below 100 psi, increase the 6270A supply pressure to equal the full scale plus 15 psi (100 kPa).

Dual range physical connections

The DPI 515 was available in dual range configurations. This configuration requires two test ports (outlet) and two supply pressures. The 6270A allows for a more simplified setup, where there is only one test port and one supply pressure.

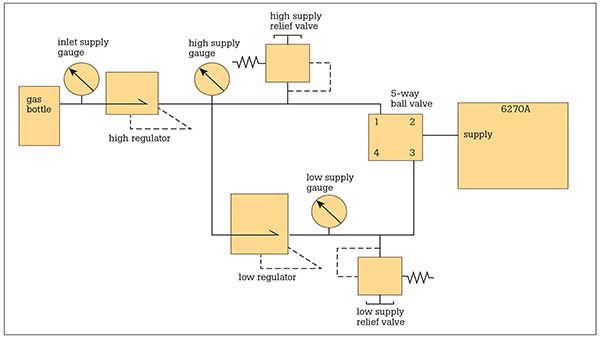

If the low range on the DPI 515 is no less than 10% of the high range (for example 3000 psi and 300 psi), then simply connect the higher supply pressure to the 6270A supply port. The low range supply pressure regulator is no longer required. If the low range is less than 10% of the high range, then the low range supply regulator still needs to be used. A simple way to set up a manual system for doing this is to use a five-way switching valve to switch the supply port on the 6270A to either the low or high-pressure supply (see figure 1). An example five-way switching valve is Swagelok part number SS-43ZF2 (note: this valve has a full scale working pressure of 2500 psi). A five-way switching valve is used instead of a three-way valve to ensure that the pressure is automatically vented when switching between supply sources. Connect the 6270A supply port to the common port on the valve. Connect the supply pressures to two of the four other ports. The two ports should be opposite each other.

By doing this, when switching from the high to the low-pressure supply, the pressure line to the controller is vented so that the low-pressure regulator won’t be back-fed with high pressure.

If the low regulator being used allows for being back-fed with higher pressure, then a 3-way valve can be used in place of the 5-way valve.

Emulating remote communication

The 6270A can be placed in DPI 515 remote emulation mode. To set remote emulation mode from the front panel, press SETUP. In the main setup menu, select INSTRUMENT SETUP and then REMOTE PORT. Pressing EMULATION MODE allows you to select DPI 515. For a complete listing of all supported commands, see the 6270A Programmers Reference Guide.

Conclusion

The flexible Fluke Calibration 6270A modular design offers a direct drop-in replacement that is also a true step above in performance. With the 6270A you get the service and support of Fluke Calibration, the industry leader in pressure calibration.

Related Products & Resources

Watch the 4-minute 6270A Introduction Video.

See the specs and learn more about the 6270A at its product page.

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- Service Request (RMA)

- Service Plans

- Technical Support

- Knowledge Base

- Accreditations

- Authorized Service Centers

- Calibration Certificates

- Community Forum

- My MET/SUPPORT

- Product Manuals (User Guides)

- Safety Data Sheets (SDS)

- Recycle Program

- Safety, Service, and Product Notices

- Software Downloads

- Warranties

- Tools

- About Us