- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

How to Calibrate a Thermocouple: App Notes Series, 4 of 4

Setting up a thermocouple calibration

Readout connection

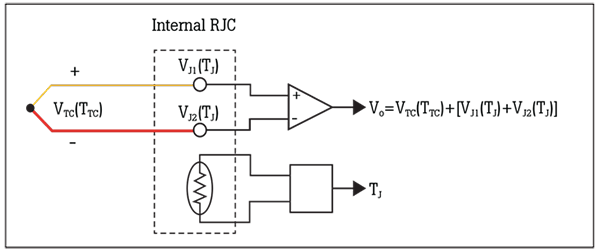

Thermocouple connection to the readout depends whether an internal or external reference junction is used. Internal reference junctions are generally used for high throughput, low-to-medium accuracy applications. There is less opportunity for error and the process is simpler. The limitation in accuracy is due to the additional uncertainty in the reference junction compensation circuit itself (usually an additional 0.05 °C to 0.25 °C).

Internal reference junction connection

Connect the 2-wire thermocouple either directly or through an extension wire to the readout observing polarity. Never use copper for the extension wire, since errors will result. Ensure all connections are tight and clean. Loose and/or dirty connections will cause spurious voltages and measurement errors. Using switches and multiplexors also will result in errors, because these devices are normally constructed of copper. Switches are available that are constructed of thermocouple materials and can be used if a large number of a single type of thermocouple must be calibrated. However, switches constructed of thermocouple materials will still contribute an error that is extremely hard to quantify. If a large quantity of thermocouples must be calibrated, a multi-channel readout or external reference junction technique is recommended.

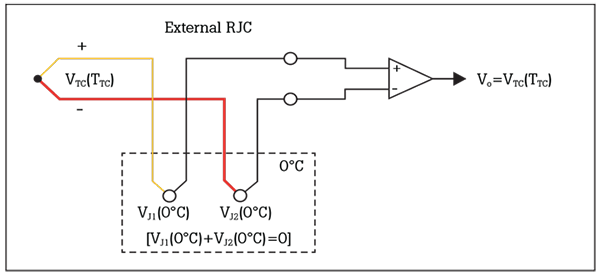

External reference junction connection

External reference junctions are capable of the highest accuracy and are almost always used for calibration of noble metal (R and S type) thermocouples. They are generally not necessary for the accuracy requirements for base metal thermocouples. External reference junctions must be used when high accuracy is required or the readout is not equipped with internal reference junction compensation (such as a typical DMM). External reference junction connection is slightly more involved with a single unit under test (UUT), but can become quite complicated when several UUTs are being calibrated and uncertainties must be kept to a minimum.

The thermocouple is connected through high-quality copper wires to the readout. The thermocouple-to-copper connections are then immersed into an ice bath to form the reference junction. The connections must be electrically insulated from one another and physically dry. Usually, the wires are welded, soldered, or twisted tightly and protected with heat shrink tubing. The group of wires is inserted into a thin wall metal or glass closed end tube and the tube is inserted into the ice bath. Immersion depth is important and depends upon the wire diameter. Usually, six to twelve inches is sufficient. The copper connecting wires are attached either directly to the readout or through a switch to the readout. Each UUT requires an individual reference junction.

Some UUTs are terminated in thermocouple connectors and cannot be conveniently connected as described. In these cases, “reference junction probes” can be constructed out of copper and thermocouple wire of the type required. The thermocouple end is terminated with connectors which will mate to the UUT connectors. These probes must be calibrated if high accuracy is required. Alternatively, internal reference junction compensation can be used. Frequently, readouts equipped with internal reference junction compensation have thermocouple connectors built in.

Probe placement

All temperature sources have instabilities and gradients. These create calibration errors and/ or uncertainties. Probes should be placed as close together as possible to minimize these effects. In dry-well temperature sources, the probe immersion points are fixed. Baths and open tube furnaces offer flexibility in probe placement. The probes to be calibrated should be placed in a radial pattern with the reference probe in the center of the circle. When using a tube furnace, thermocouples are bundled around a reference thermometer held together with fiberglass core or tape and inserted into the furnace. This placement ensures an equal distance from the reference probe to each of the UUTs.

The sensing elements should also be on the same plane. Thermocouple junctions are usually at the tip of the probe. Sufficient immersion is required so that stem losses do not occur. Generally, immersion is sufficient when the probes are immersed to a depth equal to 15 times the probe diameter plus the length of the sensing element. For example, a 0.25-inch diameter probe with a 1.25-inch long sensing element would need to be immersed a minimum of 5 inches ((15 x 0.25 in) + 1.25 in = 5 in). This rule of thumb is generally correct for probes with thin wall construction and situations with good heat transfer. More immersion is required if the probe has thick wall construction and/or poor heat transfer is present (such as a dry-well with incorrectly sized holes).

Data collection

Industry standards and guidelines require that a thermocouple be calibrated over the full temperature range in which it is used. Calibration can take substantial time, especially if several thermocouples need to be calibrated. The process involves ramping the temperature source to a setpoint temperature and recording the thermocouple reading when the setpoint temperature is stable. Sufficient time needs to be allowed at each setpoint for the temperature source to achieve stability and uniformity before recording. Then the process is repeated for each setpoint in a series covering the working temperature range of the thermocouple.

Automating thermocouple calibration with a 1586A Super-DAQ

The 1586A Super-DAQ includes an “automated sensor calibration” feature that automates the thermocouple calibration process. When the 1586A Super-DAQ is connected to a 9118A Thermocouple Calibration Furnace, the Super- DAQ will control and monitor the 9118A setpoint temperature, read up to 40 thermocouples and automatically collect data when the furnace is stable within parameters defined by the user. The Super-DAQ will then advance the 9118A to the remaining programmed setpoint temperatures, collecting data at each setpoint along the way. Once the test has been configured and started, the technician can walk away to work on other activities. This unique feature, available only from Fluke Calibration, greatly enhances lab productivity and measurement accuracy.

For more information, visit the 1586A Resource Center at www.flukecal.com.

Two calibration options

There are two types of thermocouple calibration— characterization and tolerance testing. Most thermocouples are not stable enough for characterization calibration. Typically, thermocouple probes and/or wire are tolerance tested for compliance to American Society for Testing and Materials (ASTM) error ratings. Tolerance testing involves measuring the voltage output at various temperatures and calculating the error from the standard tables.

Tolerance testing

For most applications, thermocouples are tolerance tested to verify they behave as the standard model predicts within certain limits. The ASTM has two sets of limits called “standard limits of error” and “special limits of error.” The special limits of error use tighter tolerances and were developed to cover the enhanced performance of better grade wire used in more expensive thermocouples. To calibrate a thermocouple to ASTM specifications is to determine that it follows the standard model. Individual thermocouple probes are calibrated in some cases, while entire rolls of wire require certification in other cases. The method is straightforward with no data fitting or complex calculations required.

Tolerance testing steps

- The voltage values and temperatures of the thermocouples under test are compared to the same measurements obtained from a reference standard thermocouple. The voltage values may be read directly from a digital voltmeter of sufficient precision or another readout suited for this purpose.

- The difference in “°C” for each thermocouple under test from the reference standard thermocouple temperature is noted. This conversion is done using a table of voltages versus corresponding temperatures values (in °C) for the thermocouple type. Acceptable tables must contain the same data and values found in either NIST Monograph 175 (1993) or ASTM E230-03 (2011).

- Thermocouple tolerances such as those illustrated in the Appendix A “Thermocouple tolerance summary table” are used to determine whether the thermocouples under test meet either “standard or special limit tolerances” with respect to the measurements obtained from the reference thermocouple.

Characterization of thermocouples

When tolerance testing will not provide enough information regarding a thermocouple’s voltage response to an applied temperature, a characterization of the thermocouple’s performance throughout its full range provides a more complete analysis. Thermocouple characterization is typically reserved for high accuracy applications involving noble metal thermocouples. Under most circumstances, base metal thermocouples are not stable and will not reproduce the behavior observed during characterization.

Characterization of a thermocouple involves determining the difference between the measured and standard voltage and then correcting this difference by fitting it to a second order polynomial. Fitting the data is simple in concept but can be complicated in practice. Essentially, the process is to solve a set of simultaneous equations which contain the calibration data to arrive at a set of coefficients unique to the thermocouple and calibration. An accepted “characterization” is based on principles found in NIST Special Publication 250-35, used similarly at Fluke Calibration for the re-certification of Type S and R thermocouples(1).

Characterization steps

- The thermocouples are placed sequentially in four fixed point (FP) cells. See Figure 3 for fixed-point cell summary information. The voltages of thermocouples under test are measured with respect to the four reference temperatures of the FP cells. While the thermocouple measurement junction is in the FP cell, the thermocouple reference junction is controlled in a water freeze point bath monitored by an independent thermistor standard. Note: A furnace and a reference standard thermocouple can be used in place of FP cells to provide the test temperature environment. In this case, the furnace is set to various reference temperatures so that the radially positioned thermocouples under test can be compared against readings measured by the reference standard thermocouple positioned in the furnace center.

- After the thermocouples under test and FP cell have reached thermal equilibrium, the thermocouple voltage is recorded. This is repeated for all four FP cell temperatures. Every thermocouple voltage value also includes a corresponding record of the ice point temperature in an insulated container where the thermocouple reference junction is placed.

- The unique voltage measurements obtained for the thermocouple under test at each FP provide the necessary components used to formulate a “deviation function”. This function is then added to the standard “reference function” for the thermocouple type. The final result is a “thermocouple characterization” for the thermocouple under test.

To formulate the “deviation function,” several linear algebra operations are performed to determine a “least squares solution” to the over-determined system formed by the “FP temperatures and their squared values” and “the voltage differences between the measured values by the thermocouple under test at the FP temperatures” and the corresponding “reference function” voltage values at the same FP temperatures. The least squares solution provides two coefficients which are added algebraically to the corresponding terms in the “reference function” to produce the “thermocouple characterization” function. Refer to Appendix B for a summary of the linear algebra operations.

| Freeze point element or compound | Chemical symbol | ITS-90 freeze point temperature (°C) |

|---|---|---|

| Silver | Ag | 961.78 |

| Aluminum | Al | 660.323 |

| Zinc | Zn | Zinc Zn |

| Tin | Sn | 231.928 |

| Water | H2O | Water H2O |

| (2)NIST Monograph 175, (1993), p.4. | ||

Appendix A – Thermocouple tolerance summary table(3, 4)

| TYPE B | Pt - 30 % Rh vs. Pt - 6 % Rh | Extension Grade Color = Gray | ||

|---|---|---|---|---|

| Test Temperatures | Type B Sensitivity | Nominal E | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 1250.00 °C | 10.622 uV/°C | 7.311 mV | 6.25 | 3.13 |

| 1000.00 °C | 9.123 uV/°C | 4.834 mV | 5.00 | 2.50 |

|

Range: 870 °C to 1700 °C; Tolerances:

|

||||

| TYPE E | Ni - Cr vs. Constantan | Extension Grade Color = Purple | ||

|---|---|---|---|---|

| Test Temperatures | Type E Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 870.00 °C | 77.393 uV/°C | 66.473 mV | 4.35 | 3.48 |

| 500.00 °C | 80.930 uV/°C | 37.005 mV | 2.50 | 2.00 |

| 250.00 °C | 76.240 uV/°C | 17.181 mV | 1.70 | 1.00 |

|

Range: -200 °C to 870 °C; Tolerances:

|

||||

| TYPE J | Iron vs. Constantan | Extension Grade Color = Black | ||

|---|---|---|---|---|

| Test Temperatures | Type J Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 760.00 °C | 63.699 uV/°C | 42.281 mV | 5.63 | 3.00 |

| 500.00 °C | 55.987 uV/°C | 27.393 mV | 3.75 | 2.00 |

| 250.00 °C | 55.512 uV/°C | 13.555 mV | 2.20 | 1.10 |

|

Range: 0 to 760 °C; Tolerances:

|

||||

| TYPE K | Ni - 10 % Cr vs. Ni - 5 % (Alumina - Silica) | Extension Grade Color = Yellow | ||

|---|---|---|---|---|

| Test Temperatures | Type K Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 1260.00 °C | 35.566 uV/°C | 51.000 mV | 9.45 | 5.04 |

| 900.00 °C | 40.005 uV/°C | 37.326 mV | 6.75 | 3.60 |

| 600.00 °C | 42.505 uV/°C | 24.905 mV | 4.50 | 2.40 |

| 300.00 °C | 41.446 uV/°C | 12.209 mV | 2.25 | 1.20 |

|

Range: -200 °C to 1260 °C; Tolerances:

|

||||

| TYPE N | Ni - 14 % Cr - 1.5 % Si vs. Ni - 4.5 % Si - 0.1 % Mg | Extension Grade Color = Orange | ||

|---|---|---|---|---|

| Test Temperatures | Type N Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 1260.00 °C | 36.580 uV/°C | 46.060 mV | 9.45 | 5.04 |

| 900.000 °C | 39.040 uV/°C | 32.371 mV | 6.75 | 3.60 |

| 600.000 °C | 38.959 uV/°C | 20.613 mV | 4.50 | 2.40 |

| 300.000 °C | 35.422 uV/°C | 9.341 mV | 2.25 | 1.20 |

|

Range: 0 to 1260 °C; Tolerances:

|

||||

| TYPE R | Pt vs. Pt - 13 %Rh | Extension Grade Color = Green | ||

|---|---|---|---|---|

| Test Temperatures | Type R Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 1084.62 °C | 13.575 uV/°C | 11.640 mV | 2.71 | 1.09 |

| 961.78 °C | 13.065 uV/°C | 10.003 mV | 2.40 | 0.96 |

| 660.32 °C | 11.641 uV/°C | 6.277 mV | 1.65 | 0.66 |

| 419.53 °C | 10.480 uV/°C | 3.611 mV | 1.50 | 0.60 |

| 231.93 °C | 9.168 uV/°C | 1.756 mV | 1.50 | 0.60 |

|

Range: 0 to 1480 °C; Tolerances:

|

||||

| TYPE S | Pt vs. Pt - 10 %Rh | Extension Grade Color = Green | ||

|---|---|---|---|---|

| Test Temperatures | Type S Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 1084.62 °C | 11.798 uV/°C | 10.575 mV | 2.71 | 1.09 |

| 961.78 °C | 11.418 uV/°C | 9.148 mV | 2.40 | 0.96 |

| 660.32 °C | 10.398 uV/°C | 5.860 mV | 1.65 | 0.66 |

| 419.53 °C | 9.638 uV/°C | 3.447 mV | 1.50 | 0.60 |

| 231.93 °C | 8.711 uV/°C | 1.715 mV | 1.50 | 0.60 |

|

Range: 0 to 1480 °C; Tolerances:

|

||||

| TYPE T | Cu vs. Constantan | Extension Grade Color = Blue | ||

|---|---|---|---|---|

| Test Temperatures | Type T Sensitivity | Nominal EMF | Standard Limits Tolerance (± °C) | Special Limits Tolerance (± °C) |

| 370.00 °C | 60.928 uV/°C | 19.030 mV | 2.78 | 1.48 |

| 200.00 °C | 53.150 uV/°C | 9.288 mV | 1.50 | 0.80 |

| 100.00 °C | 46.785 uV/°C | 4.279 mV | 1.00 | 0.50 |

|

Range: -200 °C to 370 °C; Tolerances:

|

||||

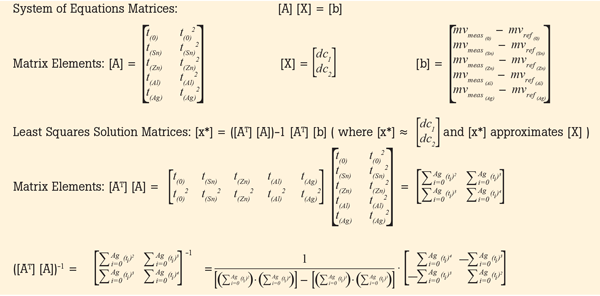

Appendix B – Thermocouple characterization linear algebra operation steps

- The fixed point temperatures and the corresponding squared temperatures are noted in a “5 x 2 matrix” named “A”. Please see the information at the end of this appendix for details on the matrices and the elements they contain described in these steps.

- A smaller “2 x 1” matrix, placed as a factor to the right of matrix “A” is used to specify the solution vector. This matrix is named “X”.

- The product of the two previous matrices, “A” and “X”, is set equal to a final matrix formed by the differences of the unit-under-test measured EMF values and the “Reference Function“ EMF values at the FP temperatures. This is a “5 x 1 matrix” named “b”.

- This system of equations has the following form: [A] [X] = [b] (5).

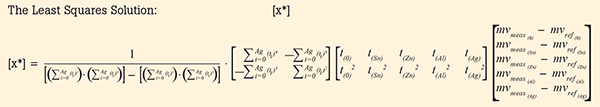

-

Using Transpose and Inverse Identity Matrices, a least squares solution “x*” for the equation in step 4 has the following form: [x*] = (([AT] [A])-1) [AT] [b] (5).

The matrix equations in steps 4 and 5 were adapted from the information in reference (5), pp. 50-54.

- The solution matrix [x*] is a “2 x 1 matrix”, and it contains the two non-zero coefficients for the quadratic (best fit) curve, “dc1” and “dc2”.

- The “Reference Function” for the Type S thermocouple can be expanded as follows:

EMFref = c0 + (c1)·t90 + (c2)·t90 2 + (c3)·t90 3 +…+ (c8)·t90 8 (where EMF is in μVdc, and t90 is in °C).

- The “Deviation Function” or quadratic best fit curve is

EMFdev = 0 + (dc1)·t90 + (dc2)·t902

- Finally, if the “Deviation Function” in step 8 is added algebraically to the “Reference Function” for Type S in step 7, the resulting superposition equation is the unique “Thermocouple Characterization” or a particular Type S thermocouple under test.

EMFchar = c0 + (dc1 + c1)·t90 + (dc2 + c2)·t902 + (c3)·t903 +…+ (c8)·t90 (6)

The characterization matrices, the elements and the least squares solution [x*] (temperatures in °C, and EMF in mVdc)

References

- NIST Special Publication 250-35, “The Calibration of Thermocouples and Thermocouple Materials”, G.W. Burns and M.G. Scroger, National Institute of Standards and Technology, Gaithersburg, MD, 1989.

- NIST Monograph 175, “Temperature-Electromotive Force Reference Functions and Tables for the Letter-Designated Thermocouple Types Based on the ITS-90”, G.W. Burns, et al, National Institute of Standards and Technology, Gaithersburg, MD, 1993.

- ASTM E230-03, “Standard Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples”, ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA, 2003.

- Omega Engineering Technical Reference, Section Z. https://www.omega.com/ temperature/Z/zsection.asp (used for TC color codes)

- Geometric Transformations and Image Warping, University of Utah, SCI (School of Computer Imaging) Institute, School of Computing, an MS-PowerPoint Presentation by Ross Whitaker, as modified by Guido Gerig, Class CS6640, Fall, 2012, pp. 50-54.

- Thermocouple Report of Calibration for Type S, latest version, Fluke Calibration, American Fork, UT, p. 2 of 14.

Keep learning. See the other app notes in this series

How to Select Thermocouple Calibration Equipment

Calculating Uncertainties in a Thermocouple Calibration System

See Recommended Products

Thermocouple calibrator selection guide

5649 / 5650 Type R and Type S Thermocouple Standards

Get help

Customer and technical support

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- Service Request (RMA)

- Service Plans

- Technical Support

- Knowledge Base

- Accreditations

- Authorized Service Centers

- Calibration Certificates

- Community Forum

- My MET/SUPPORT

- Product Manuals (User Guides)

- Safety Data Sheets (SDS)

- Recycle Program

- Safety, Service, and Product Notices

- Software Downloads

- Warranties

- Tools

- About Us